Spirit Airlines Airbus A321 covered in snow at La Guardia International Airport.

De-icing and anti-icing in Miami is something I hope to never have to do, but if you are flying anywhere north (or really far south) you will eventually encounter a time where you will need to de-ice. For most, this is something you will do once you begin flying jets with a strict schedule. These airplanes are designed for what is referred to as flight into known icing conditions(FIKI). You definitely won’t find me flying around in icing conditions on purpose in a light aircraft. No matter whether it has anti-ice or de-ice capabilities.

What is De-Icing?

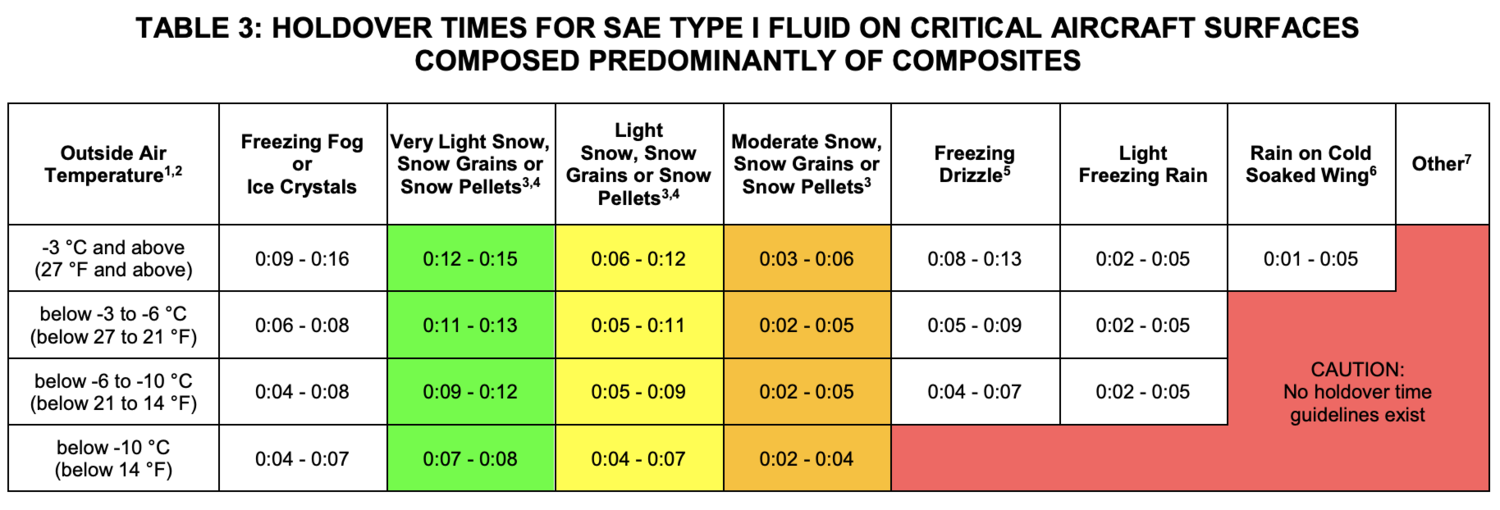

De-Icing is the first step in getting the aircraft in the air during cold weather operations. All we are doing during de-icing is removing any contaminants (ice) on the aircraft. It is important to note that if icing conditions exist, the ice will form again. There are different types of de-icing fluids that can be used on the aircraft. They all have different Hold Over Times (HOT), this is basically a guideline as to how long this fluid will hold up to the current conditions. These times are calculated using the table specific to the fluid, referencing the current Outside Air Temperature (OAT) and conditions. See below to table 3. There are times where all you need is de-icing and no anti-icing. This usually occurs when the aircraft has been sitting on the ramp overnight and it has frost or standing snow on its surface. In this case, since there is no snowfall, the aircraft can simply be de-iced and is ready for takeoff.

Let’s say the OAT is currently -5°C, and we are in very light snow. Using the table below, we can expect a HOT of 11-13 minutes, remember this is from the time that the de-icing begins. This means that by the time they finish, you probably won’t have a HOT if there is light snow. Hence why we use anti-icing fluid.

What is Anti-Icing?

Airbus engine with snow inside the nacelle. Blades covered in ice can cause vibration and engine damage.

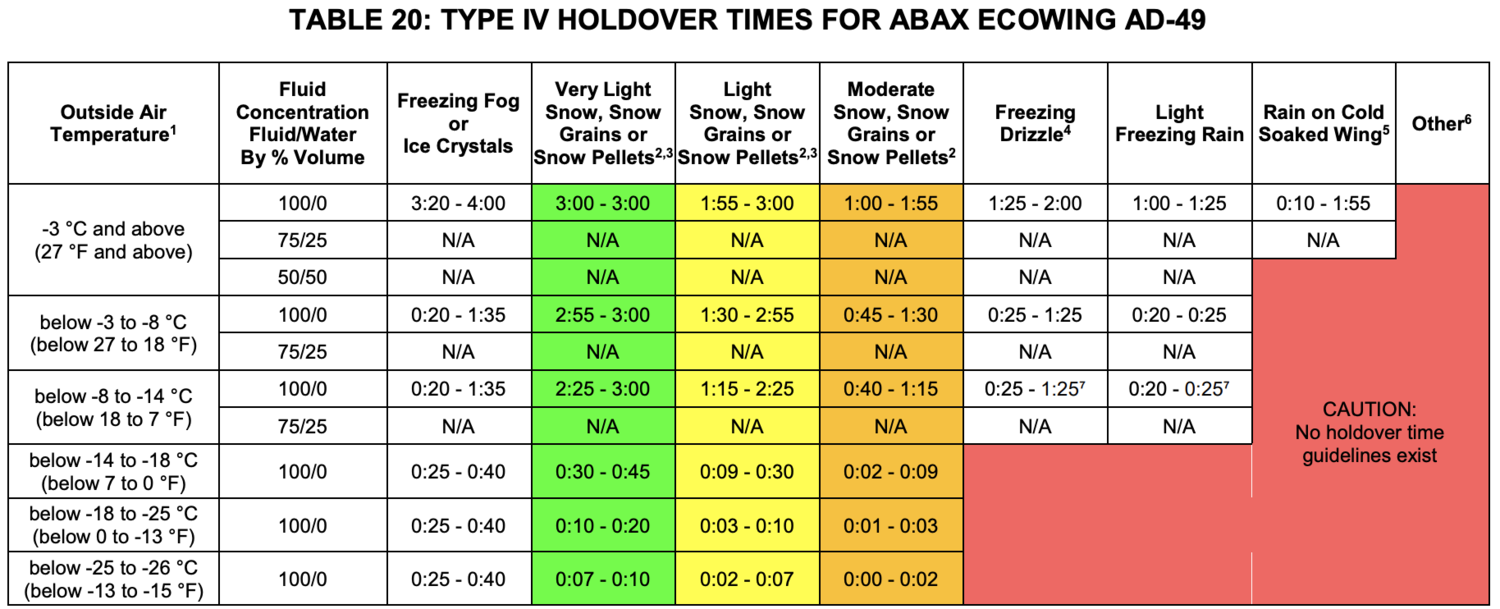

Anti-Icing is a process where you add a fluid onto a “clean aircraft” to protect it from ice formations. These fluids also have a HOT time, but they are way longer than those of any de-icing fluid. Just like de-icing fluid tables, anti-icing are also calculated the same way. These times are for guidance, and as pilots, we must determine if the aircraft is safe for flight based on contamination checks. Through inspections, we can determine whether the aircraft’s anti-ice has failed, which may require a respray. There have been occasions where I’ve had to de-ice and anti-ice the aircraft multiple times due to runway closures or delays.

In the example we covered above we say a HOT of only 11-13 minutes and there was very light snow. Because the time was not going to be enough to get the airplane in the air safely, we decided to apply Type IV fluid at 100%. The application began at 1400 of Ecowing AD-49. Based on the same conditions we now have a HOT of 2:55-3:00 hrs. Much safer!

It’s important to note that these times don’t mean we will blast off into the air just based on the table, we still inspect the aircraft before takeoff, and if there is any doubt that the fluid has failed, we will return to the de-icing pad and start all over again. I have had instances where I was in the de-ice pad and the fluid failed before they even finished applying it. Needless to say we had to start the process all over again.

There are 4 types of de-icing fluids:

Type I (orange)- normally used as de-icing, and is always applied hot.

Type II (clear/straw)- normally used as anti-icing, used for aircraft with rotation speeds above 100 knots

Type III (yellow)- normally used as anti-icing, used for aircraft with rotation speeds below 100 knots

Type IV (green) - very similar to Type II except it has significantly long Hold Over Times (HOT)

De-icing pad at the Dallas/Fort Worth International Airport

FAQ

How do you know if you need to de-ice?

a. During the preflight inspection we determine if the aircraft is contaminated, if so we will then proceed to de-ice, and depending on field conditions we would apply anti-ice.

How much does de-icing and anti-ice cost?

a. Not cheap is what I’ve been told. It all depends on what fluids they use, now we have forced air applications as well as fluid mixed with water to save on the costs. At the end of the day, it comes down to how much fluid is used and how efficient the iceman is.

What not to do

What are some other ways to de-ice?

a. Researchers are continuing to find new ways to prevent ice from forming. In the past, Soviet jet engines were repurposed as snow blowers to melt away excessive snow. While this may seem like a great way to repurpose old engines, extreme heat and expensive instruments aren’t a good match—especially if materials are going from freezing temperatures to scorching hot in a matter of seconds.

What are the environmental impacts?

a. According to studies conducted by the EPA, de-icing chemicals could potentially impact water quality when proper controls are not in place. Fortunately, de-icing pads, like those found in many airports across the north do a great job of collecting excess solutions below the pad for recycling.

.png?width=178&height=50&name=Aviator%20Zone%20Academy%20(5).png)

Submit a Comment